Add to Cart

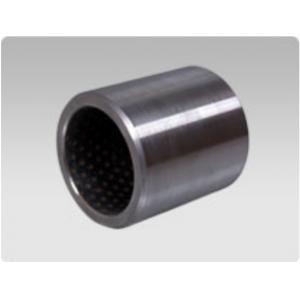

Water Conservancy Project Bearings , INW-TSG-150 Steel Backed Bronze Plastics Bearings

INW-TSG-150 are applied in water conservancy project .This kind of hardened steel bushings made of high quality low-carbon steel or stainless

steel with special techniquie .The surface can be carburizing to imporve the hardness.They're widely used to automobile industry and heavy-duty

machinery etc.

| Model | TSG-150 | TS-2 | |

|---|---|---|---|

| Shell thickness (mm) | 1-1.5 | 0.5-0.8 | |

| Allow wearing depth (mm) | 0.5 | 0.3 | |

| Maximum carrying capacity(N/mm2) | 100 | 40 | |

| Coefficient of friction | Aging | 0.15 | 0.14 |

| Static (water) | 0.12 | 0.12 | |

| Dynamic(min) | 0.08 | 0.07 | |

| Appearance | To allow a small amount of plastic pore | ||

Headed Press Fit Bush is used when the number of parts to be produced does not necessitate the replacement of the bushings during the life of

the Jig. The O.D. of Press Fit Bushings can be supplied with grinding stock for fitting in the Customer's Plant or finish ground to a Press Fit size.

Our advantages:

1. Use 100% Raw material, strict incoming inspection.

2.Overpressure sintering, increasing the densification of the alloy teeth and increasing the 30% life span.

3.Can be customized according to the requirements of the customer.

Production Process:

Milling--Proportioning as required--Wet grinding--Dry--Granulation--Press--Sinter--Inspection--Package

Specifications:

there are tungsten carbide bushing specifications as below showed, we also accept your inquiry with drawings.

| Unit(mm) | ||||

| φd(r8) | φd(E9) | Seat Bore(f7) | Diameter of axle(f7) | L0-0.5 |

|---|---|---|---|---|

| 100+0.105 +0.051 |

80+0.134 +0.060 |

100+0.035 +0 |

80-0.030 -0.060 |

60≤L≤120 |

| 120+0.108 +0.054 |

100+0.159 +0.072 |

120+0.035 +0 |

100-0.036 -0.071 |

|

| 140+0.126 +0.063 |

120+0.159 +0.072 |

140+0.04 +0 |

120-0.036 -0.071 |

100≤L≤150 |

| 180+0.131 +0.068 |

150+0.185 +0.085 |

180+0.04 +0 |

150-0.043 -0.083 |

100≤L≤200 |

| 220+0.152 +0.080 |

190+0.215 +0.100 |

220+0.046 +0 |

190-0.050 0.096 |

150≤L≤250 |

| 300+0.179 +0.098 |

260+0.240 +0.110 |

300+0.052 +00 |

260-0.056 -0.108 |

150≤L≤300 |

| 360+0.203 +0.114 |

320+0.265 +0.125 |

360+0.057 +0 |

320-0.062 -0.119 |

200≤L≤350 |

| Non-standard size of the original processing | ||||